Alfa Sprint Service

Dé specialist in LED-verlichting en elektronica

Ontdek de voordelen

Dankzij onze expertise:

|  |  |

| Bespaar je tot 75% op energie | Maak je jouw producten aantrekkelijker voor de klant | Heb je géén onderhoudskosten meer |

Vraag hier gratis onze expertise aan

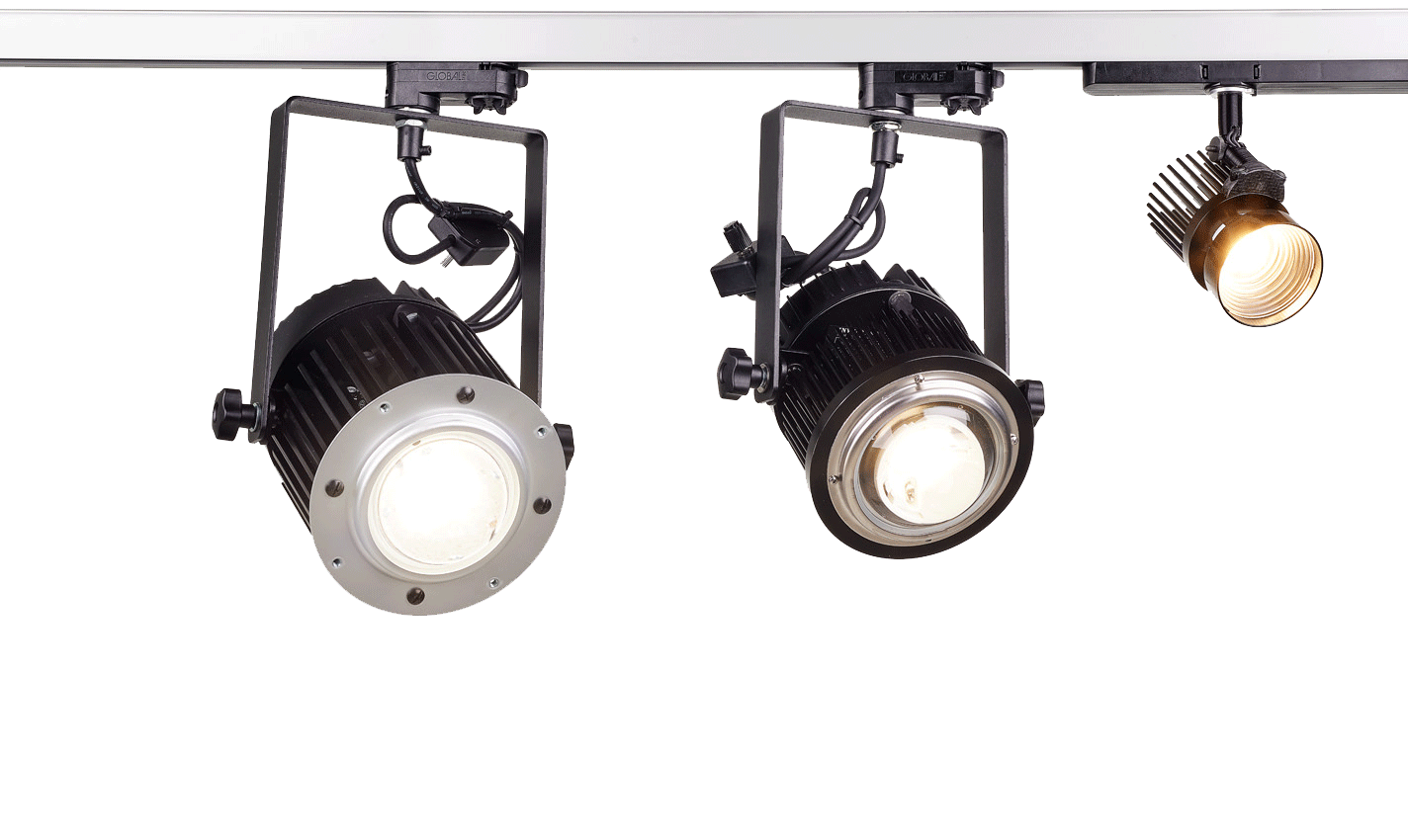

Led verlichting

Besparen op verlichtingskosten? Kies dan voor professionele LED verlichting. Het is niet alleen extra duurzaam, het is bovendien verkrijgbaar in allerlei soorten en maten. Voor elke toepassing leveren of ontwerpen we de meest geschikte uitvoering, hetzij voor gebruik thuis, op kantoor of in de werkplaats.

Lees ook meer over onze led verlichting voor thuis, over led verlichting voor kantoren of led verlichting voor de werkplaats.

Lichtstudie

Wil je de perfecte lichtinval thuis of op kantoor? Of door winkelverlichting je producten perfect tot z’n recht laten komen? Laat ons dan een professionele lichtstudie voor je maken. Zo kan je optimaal genieten van een klare kijk op de zaak.

Domotica systeem

Je verlichting en apparaten thuis of op kantoor bedienen met één druk op de knop? Ontdek dan ons eigen AlfaStar domotica systeem: zeer zuinig in verbruik, eenvoudig te bedienen, comfortabel, veilig, duurzaam én betaalbaar.

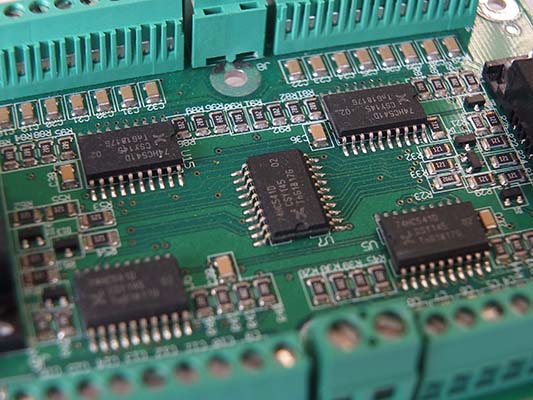

Elektronica ontwikkeling

Op zoek naar advies voor je elektronica project of wil je onderdelen hiervan uitbesteden? Wij ontwikkelen zowel elektronische hardware als software voor toepassingen binnen de wereld van de elektronica, zowel in regie als op projectbasis.

Recente projecten

Lees hier onze recente berichten

Download onze folder

En kom alles te weten over de eenvoudige veelzijdigheid van ons AlfaStar domotica systeem.